Conveyor Maintenance

Conveyor Maintenance

Grace Engineering and Technical services (G-serv) company, we use engineered products and services to provide our customers with the best solutions to their material handling applications as the channel partner of Thejo engineering Solutions India limited. Thejo Co. founded in 1974 and now they are one of the few companies in the sub-continent offering manufacturing, marketing and servicing activities under one roof. Thejo has global presence with subsidiaries in Australia, Saudi Arabia, Brazil and Chile. Headquartered in Chennai with 5 manufacturing plants and R&D Centre, approved by the Department of Scientific and Industrial Research, Ministry of Science and Technology of India (DSIR).

Industries

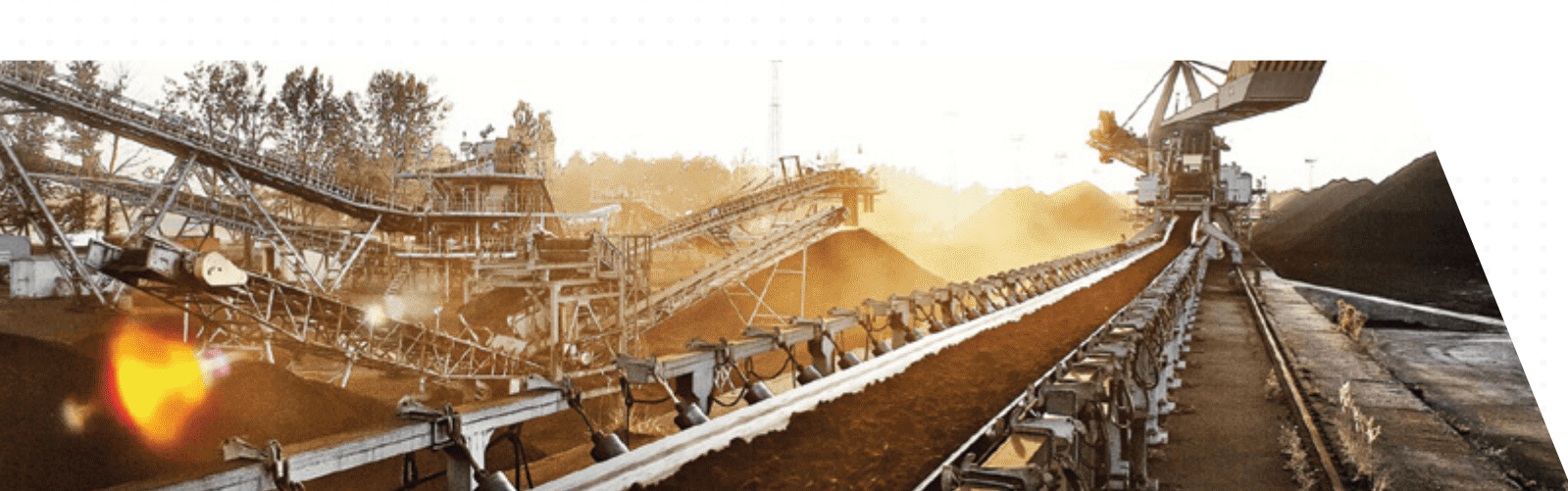

We have all the conveyor products and services to meet your particular industries needs.

Aggregate

Agriculture

Airports

Cement Operations

Coal Fired Power Plants

Grain

Iron Ore

Oil & Gas

Open Pit / Hard Rock Mining

Waste & Recycling

Under-Ground Mining

Ports & Terminals

Services

CONVEYOR BELT Splicing&Valcunizing

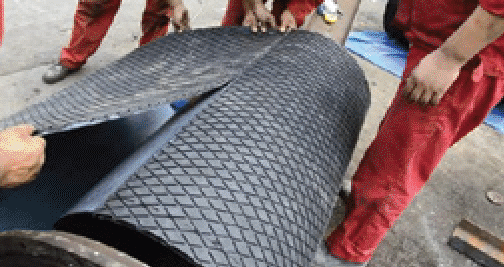

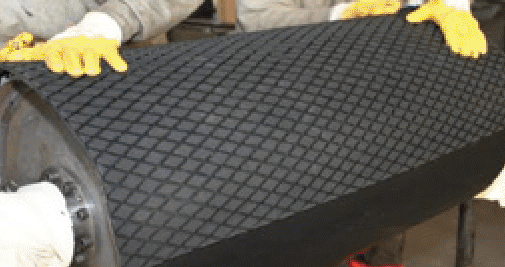

PULLEY Lagging

PULLEY Reconditioning

CONVEYOR ROLLERS & FRAMES Replacement

CONVEYOR Maintenance

CONVEYOR Installations

CONVEYOR CHUTE & LINING Installations

ENDLESS Conveyor Belt

Our Conveyor Maintenance, and Repair Services include, but not limited to:

- On-site Conveyor maintenance

- Belt repairs including re-splicing, re- clipping, hot and cold Vulcanizing.

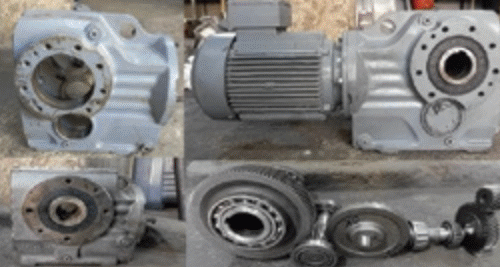

- Maintenance, trouble shooting and replacement of conveyor drive unit (including motor, coupling, gearbox, and base).

- Conveyor roller and frame replacements

- Skirt replacement and adjustment

- Rubber lining

- Impact bed installation and maintenance.

- Conveyor pullies change out and repairs.

- Pipe conveyor Maintenance

- Bucket elevator maintenance Etc..

Conveyor Belt Splicing and Vulcanization

- Fabric , Steel Cord& PVC

- Hot Vulcanizing Services

- Cold Vulcanizing

- Mechanical Fasteners

- Light Weight Conveyor Belting.

- Belt Stringing Services

Other Conveyor Services

- Pulley Lagging Hot & Cold

- Component Change Out - Idlers, bearings, drives

- Mechanical Work

- Skirting adjustment and replacement

- Wear Liner repair and replacement

- Scraper Replacement

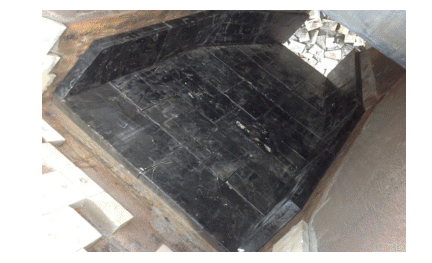

Conveyor Chute Installation and Lining

Chute Lining and Skirtboard are designed to be an integral part of a conveyor system. Our pre-engineered chute lining products and cushions the chute from the material being handled, Skirtboard prevents fugitive materials from escapeing and damaging the conveyor loading areas. We can build, design, fabricate and install chutes, and also repair and re-align existing chutes. Combining and maximizes material transfer, promoting efficient flow, dust suppression and reduced buildup inside the chute.

- Steel Liners

- Ceramic Liners

- Urethane Liners

- Plastic Liners

- Chromium Carbide Liners

- Rubber Liners

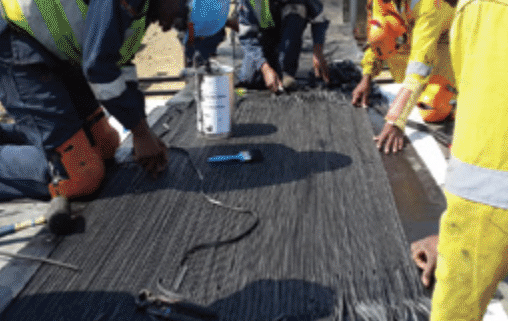

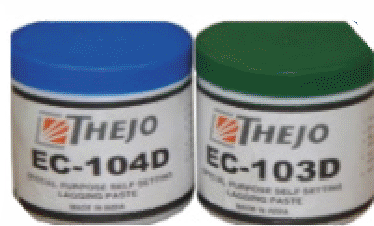

BELT SPLICING SOLUTIONS

Our ongoing recruitment and training program ensures that our conveyor belt splicing teams are the best in the business. At G- Serv we offer both on-site and endless splicing services using our facilities. Our technicians are proficient in the splicing of all types of conveyor belts – plied rubber, solid woven PVC, and steel cord. With this kind of flexibility, you can be sure that we will provide your company with an unrivalled level of service.

- TEZ Cold Splicing Solutions

- TEZ Hot Splicing Solutions

- TEZ Fabric Splice Kits

- TEZ Repair Putties/Paste

- ELIFLEX Conveyor Belt Repair Paste

- TEZ Steel Cord Splice Kits

COLD SPLICING CHEMICALS

HOT SPLICING CHEMICALS

REPAIR CHEMICALS

Fabric Belt Splicing

Steel Cord Belt Splicing

Repair Materials

Splicing Tools

Inspection and Maintenance Programme

Maintenance services mazimize product output and overall conveyor performance. Routine conveyor inspection and maintenance will keep small problems from turning into major ones. Our certified technicians know to maintain plant equipment and haldle scheduled maintenance and emergency service 24 hours a day. Your conveyor equipment will be routinely serviced and checked to insure maximum performance and increased productivity from less downtime.

- Scheduled conveyor walkthroughs

- Identification of problems areas

- Detailed plan of attack to change and improve

- Installation of products

- complete maintenance schedule